Week 220: Sparks fly

Dry docking is imminent as the welders start putting Clair back together. The weather is getting colder and we hunt down some warmer cloths.

We thought the bus seemed unusually crowded when heading into the city last Sunday. Everything is shut on Sundays here, so we thought there might be a festival. As we walked through town, exploring a free art exhibition and soaking up the sights, we noticed all the shops were open! Turns out that on the first Sunday of every month, it's Sunday shopping in Gent. While I miss the easy access to 7-day shopping in the US and Australia, I quite like this as a solution. It is a very typical Belgian balance between making it available and ensuring people get time off.

Scenes from Gent on Sunday afternoon. We enjoyed the free art installation in part of an old church.

On Monday, we were straight back into demolition. I removed the hatches in the two bedrooms. It's no wonder they were leaking. The sealant was old and multi-layered, the wood was rotten, and the insulation was damp. I'm not sure what the life span of a Vetus hatch on a boat is, but they should probably be pulled and resealed every ten years. Thirty years (since the middle room was installed) is far too long!

There is something very satisfying about ripping things out and making a mess! We (ahem, Karina) are very good at cleaning up each day and making sure that Clair de Lune remains habitable (although that will come to an end shortly).

We continued to sand and varnish the windows, a job that suddenly became more challenging as the weather cooled. The fog set in on Monday, and it's been seven days since we saw the sun! Our oil-based stain is taking longer and longer to dry, and we can't do the outside because of the moisture in the air. All of this is an annoyance but not a problem—there's still lots to do inside Clair de Lune.

I do work, too, and not just take photos of Karina working. After all the sanding, she took on the challenge of cutting out the extraction fan with the multi-tool.

Lots of progress was made with the architects and the builders. We have our high-level plans locked in now, and after four rounds of visits from builders, we've selected one to work with. Because we're moving so fast (although it only sometimes feels like it), we're following a different process than is typical. It's difficult for builders to quote because a) we still need to detail everything, and b) the boat itself is challenging. The focus has been finding someone who understands our budget and vision and wants to do something unusual. With Philippe, we've found the right match.

Fog set in on Monday, but it hasn't shifted since. It goes a little higher and a little lower, but it never goes away.

Three of the four builders that visited ummed and ahhed about the sub-floor of Clair de Lune. This is the section immediately above the hull on which the boat's internal structure rests. No one wanted to be definitive, but they all questioned if it might contain asbestos. We've found an asbestos testing company that'll take samples away for testing. Fingers crossed, it's not. It shouldn't be – it was laid in 1995, which SHOULD be late enough for people to stop using it. As one of the builders said, "A shame, really; it's a fantastic building material, except for the bit where it can kill you."

Meetings with the builders all took place on Clair de Lune.

We headed into Dok Noord to visit the architects on Wednesday to choose a builder together, a process that takes a couple of hours out of our day by the time we walk there, meet, shop, have a coffee and walk back. The good news is we're all on the same page and progressing nicely.

Martin, the electrician, returned to the boat to take detailed measurements and set a start date for the electrical upgrade. Of course, as we dive into things, some minor things have to change! The existing battery compartments aren't big enough for the new batteries, so they must be modified. The solar panels we picked don't fit the space, so we need to either downsize and change the layout or drop a panel. By mid December, we should have the bulk of the electrical work completed (we will wait on the solar panels until after we complete painting).

Which brings us to Thursday morning. Peter came by with a work order and confirmed that we will go into the dry dock on Wednesday this coming week. He said the welders have time and can start filling those hatches I've been ripping out. In typical Peter fashion, he said, "maybe tomorrow", but two hours later, the fabricator was framing the metal. By the end of the day on Thursday, two hatches were welded closed.

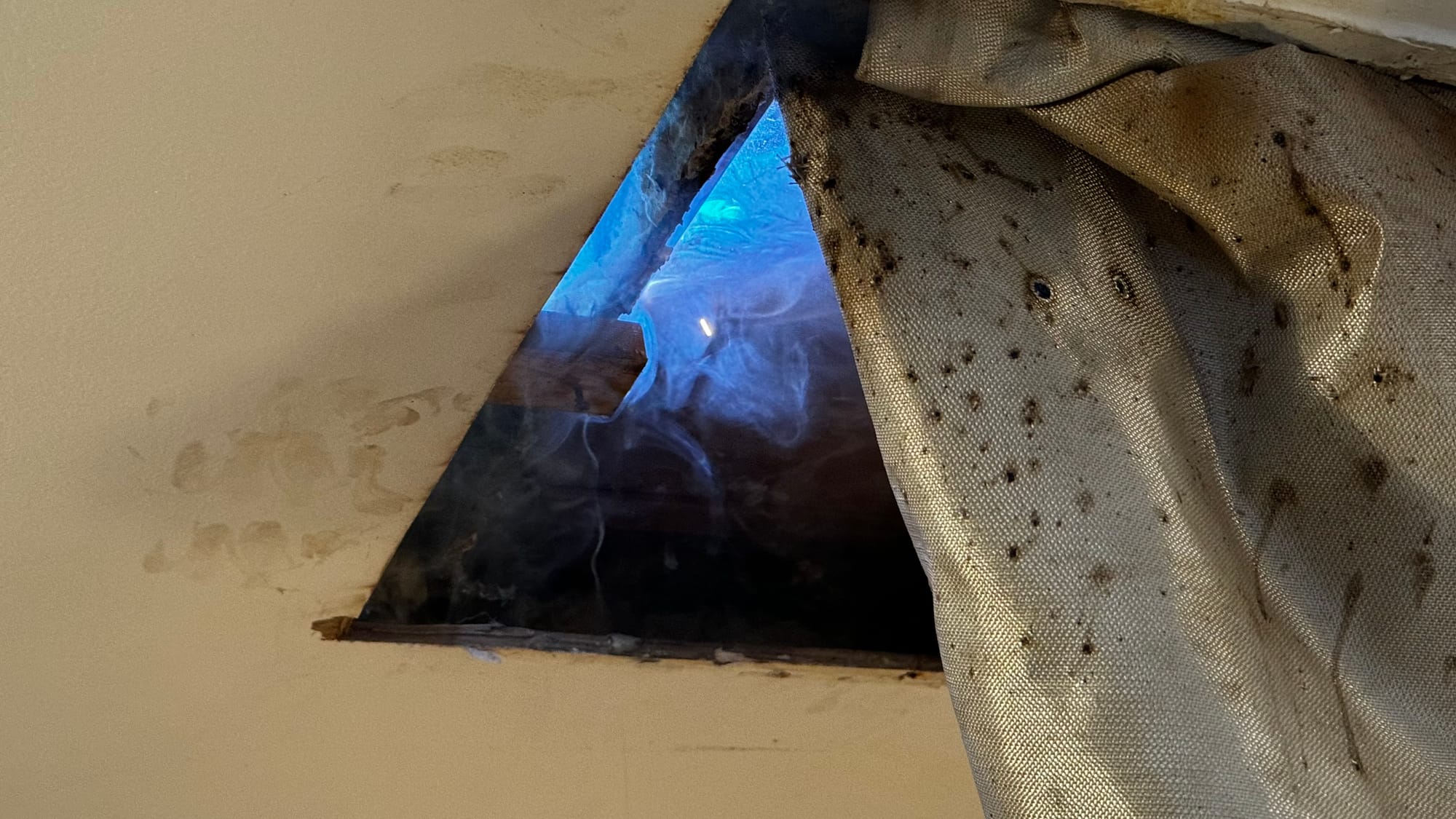

Welding up the front hatch. We realised because of a support beam radiating heat, we needed to cut a bit more ceiling.

The large hatch for the old staircase was a bigger job and took most of Friday, but it's also closed now. Some of the roof structure was repaired. They also welded up the hole for the kitchen extraction fan. The location is moving and will most likely be a filtered fan (no hull holes) instead.

We are repairing the hole for the old stairs. There is a termite nest in there! It is not a significant issue on a steel boat; we think they lived in the damp from the leaky old hatch and fed on the softwood that mounted it, which has all been removed now.

I've not worked with welders before. It's a fascinating and noisy process. It's also quite hazardous. One of us has to sit on fire watch inside the boat the whole time. Our insulation is supposedly fire-resistant, but it's also ancient, and on one occasion, it did start to smoulder and smoke. It was easy enough to pat it out, but you must always keep your eye on it.

There are parts of the boat that they won't weld. We asked about modifying the battery compartments in the engine room, but they refused. There is too much oil residue, and they don't consider it safe. So we're taking a different approach there. (Also, I need to clean the bilge under the engine, too!)

There is about a half-day of welding left. They will install four new hardpoints (metal rings) to attach our fenders and repair a small hole I made in the coachroof for the Starlink.

On Saturday afternoon, we took some time off. Karina went for a haircut. Her hair is now very short, which is much more practical for working on the boat. Afterwards, we walked into Gent and shopped for some warmer clothes. Our Greek winter clothes weren't warm enough, so we needed new jumpers.

This coming week is going to be mayhem, even for us! More welding and planning meetings with the architect and the builders. We are moving Clair de Lune into the dry dock and relocating us back to the apartment. I'll have my basal cell carcinoma removed on Thursday under a local anaesthetic. Karina has her first appointment with a rheumatologist at the University of Gent Hospital. The surveyor will visit so we know how much (if any) over-plating we will require on the hull. And the sand-blasting should commence.

It is all hands on deck, action stations and time to get really dirty!

Until next time,

Tim & Karina