Week 222: Sandblasting is complete

The prop shaft is replaced, overplating and sandblasting completed. The renewal of Clair de Lune continues apace!

First off, a welcome to the new subscribers. 👋

Our (not-so) little project has attracted some interest among The Barge Association (aka DBA) members. We had a lovely feature in their newsletter, which directed a few people here and to the videos. If you're barge curious, the DBA website has a massive number of resources, and it's well worth the membership. We've had several questions answered and been put in touch with many helpful people through their forums.

Sunday was a typical relaxed day for us. We headed to the Lederberg Markets and, for the most part, took things slow and easy. The weeks are tiring; we work hard each day, so stopping for a breather is essential.

Local market and our eBikes tucked up inside the apartment

On Monday morning, we split up. Karina went to the shipyard, while I went to the hospital for a checkup on my ear after surgery last week. Everything is going well and healing nicely, so it was off for a ride from the hospital through the centre of Gent to meet Karina.

The rented electric bikes are going nicely. Optimising the route has taken a few runs, but we're pretty happy with it now. The bikes take roughly 25 minutes to go door-to-door, faster than public transport (which could take 30 minutes to an hour and a bit, depending on connections).

The shipyard arranged for their "shaft guy" to come in on Monday. A retired man, he specialises in machining propellor shafts. Together with Vassilly, they removed the rudder, propellor, and shaft. The shaft is mounted in two sections, joined by a coupling. He thought this wasn't desirable, but it probably happened when the "new" Perkins motor was mounted in 2010. The motor sits forward where the old one would have been, and the theory is that instead of replacing the shaft, they just extended the old one with a coupling.

Removing the propellor shaft

Removing the shaft was 100% the right call. The ball bearings on the coupling were failing, and the damage on the end of the main shaft was extensive. We made the call to replace it. If you're in a dry dock, especially if it's been a couple of years, removing the shaft to inspect it is relatively cheap for peace of mind. You can only tell what's happening once you get in close.

They wanted to replace the shaft with a single new one, but unfortunately, we were time-limited, and suitable material was not available anywhere! Therefore, the decision was made to replace the end and renovate the coupling. They have improved the coupling's mounting system, repaired the ball bearings, created a new propeller nut, and done other small things.

The propellor was sent away to be polished and rebalanced and has come back gleaming and sharp on the edges of the blades. Along with the replaced bearings, new shaft and seals and the other improvements, they estimate a 20% improvement in fuel consumption and a reduction in engine noise. We're excited to find out!

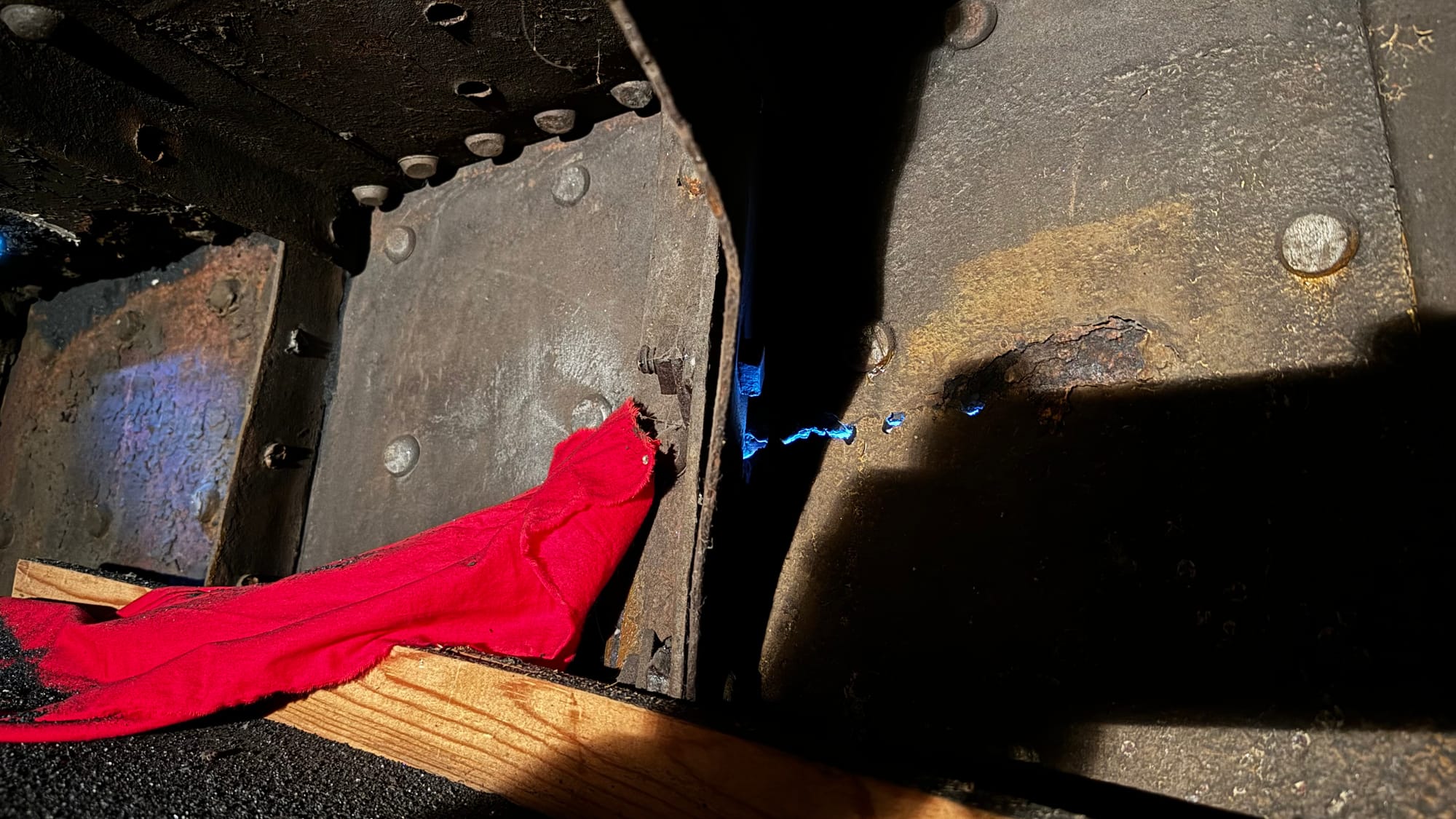

Welding new plates to the weak spots on the hull. New magnesium anodes.

Next was welding. We spent two days on fire watch as the overplating was done in several spots on the hull. This is a tedious but essential job: You watch the glowing inside of the metal to ensure nothing catches fire. It's all good so far! The team is very good at what they do, and it's been a smooth process. We were relieved when we thought it was all completed on Tuesday.

And, of course, there's the other big job. Sandblasting and painting. This progressed on and off but kicked off again on Wednesday. We were told to stay away as we couldn't access the boat while the sandblasting happened. I received a call on Wednesday afternoon that the sandblasting of the deck had found several small rust spots through the deck plate. I went to the shipyard to see Clair de Lune, which is now mostly primed, with a few places that need attention.

It looks like the welding still needs to be completed 😭. We're pushing ahead with the painting as we want to get out of the dock, but we'll have them weld those holes closed and then grind and prime them ourselves. The deck will only be primed now, so it's easy enough to fix those and prime them afterwards without impacting the final coat.

The problem is the bits (bollards) at the bow, they let dirt behind them which rusts through. We've cleaned them out now and we're going to plate over the front so no more water and dirt goes behind.

Finally, on Thursday, the sandblasting was completed (around the stern), and I could head out to the shipyard again. This time, I checked in with the shaft guy about the progress and looked around the workshop at everything they were doing. They are a talented group. I guess it makes sense, but I'm so used to a world where if you buy something, it's "off the shelf," the idea you'd custom make something from a piece of steel from scratch is fascinating.

New propellor shaft and the prop back from the balancer.

Thursday afternoon was a significant milestone. We were back at the Marge Architecten to review the latest iteration of the plans and examine material selections. It was fun to be off the ship and in an office while still making constructive progress on the project. We're excited about the material palette we've chosen, and this allows the next phase–measurements on-site by the builders—to commence.

Friday was a chilly ride to the shipyard, with the temperature hovering around freezing. Ice was on the ground in the yard, and we felt winter starting to close in. Our goal was to clean. Now that the sandblasting is completed, we need to eliminate all the sand accumulated everywhere! The interior was filthy. Any tiny crack, including gaps around windows, rust holes, air vents, etc... the sand infiltrates everything. It took several hours, but Clair de Lune now looks respectable again. It's a losing battle in some ways. After all, we're demolishing parts of the interior as fast as we can clean it, digging holes in walls, and removing parts of the bathrooms, but it makes us happy to keep the site safe and tidy.

We also had good news: The subfloor is not asbestos, which is a significant relief. We were worried that we'd have to tear everything up (and pay expensive safety considerations while doing so), but fortunately, that's not an issue.

A very dirty boat full of sand, especially in the forepeak. Bringing some wool insulation to the boat to fill in some of the holes in the ceilings now the welding there is complete.

You win some and lose some, however. The local representative of our central heating boiler has refused to come and work on it! This seems to be a particularly Belgian issue–there are a lot of regulations to comply with here (in Europe in general, too, I suppose), and ships seem to fall into a "no man's land". It's easier for some companies to refuse the job rather than do the work with the uncertainties of liabilities. It's annoying, not because we won't find someone who works on ships, we will, but we had hoped for a swap and replace solution. The most frustrating part is that the physical installation of the boiler is no different from any domestic one.

Saturday, we slept in, then headed back to the yard. Karina completed the electrical plan for the architects. At the same time, I washed down the boat again, removing the last sand from the exterior (hah! Not even close) in preparation for the final coats of paint to start on Monday. I had five layers of clothes up top (shirt, warm jacket, coveralls, waterproof overalls and a spray jacket) and three on my legs (jeans, coveralls and waterproofs) as it was 3C outside while spraying water everywhere. That's another job I'm pleased is done.

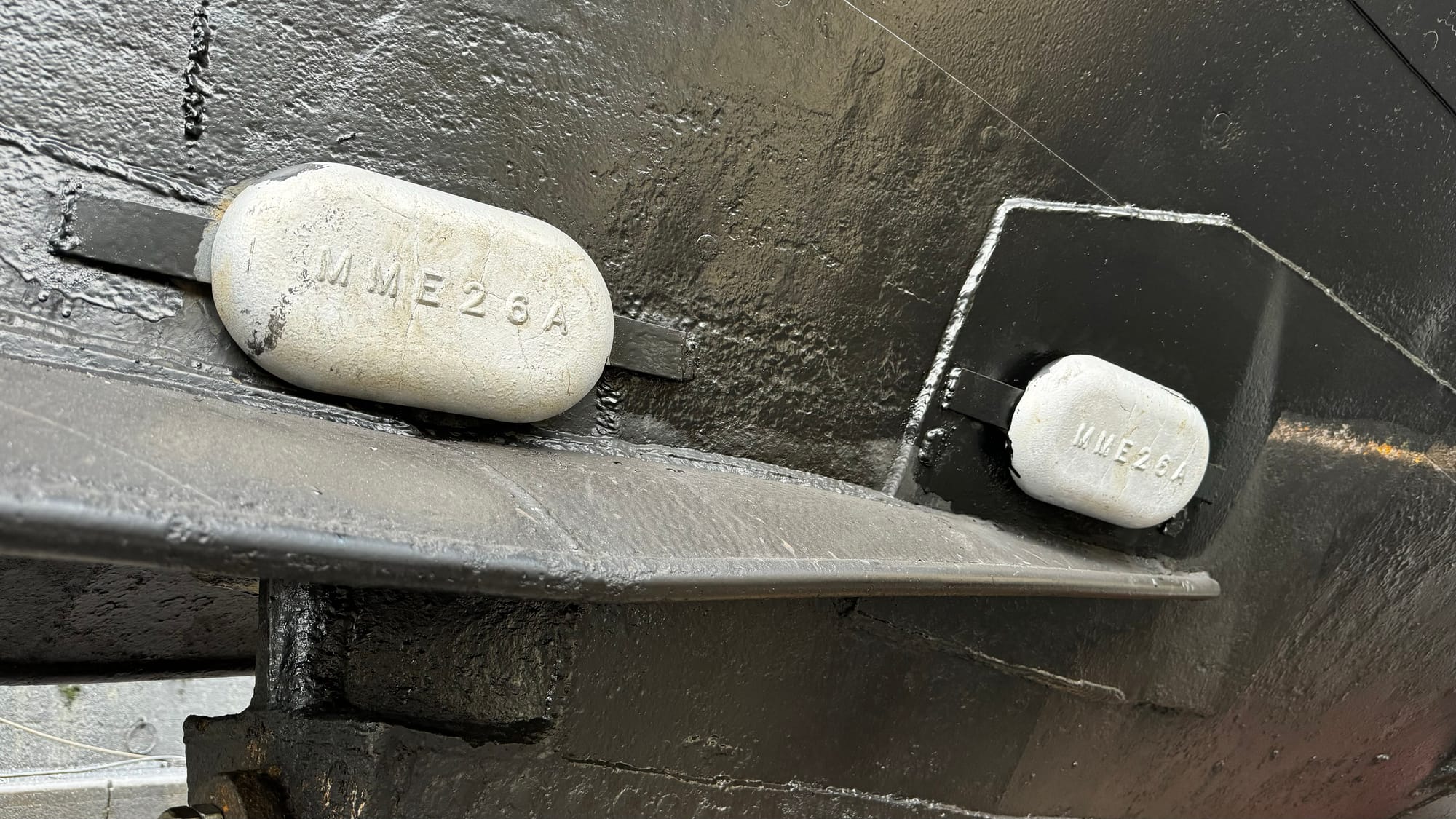

Old anodes, new prop shaft and new anodes.

As expected for a boat without much handover, we continue discovering new systems. As part of the survey and lifting Clair de Lune out of the water, we found some water intakes we needed to familiarise ourselves with. We've been tracing some pipes from those that connect to a pump hidden under one of the diesel tanks. There's an on switch, which I've never been able to get to work, but with the electrical work, I've discovered a circuit called "Pompe", which is only active with the generator. We might have a deck wash system, which would be an exciting revelation! Or, we might have an emergency bilge pump. Or we might have a ballast pump. Or, likely, we have all three, and it's a matter of how you configure the manifold. It will have to wait until we're back in the water to explore further–hopefully I don't sink the ship!

Well, that's what's been going on this week, quite a lot when you look back at it, although not as many photos as I'd like.

Until next time,

Tim & Karina