Week 223: Discover Delfine

We officially rename from Clair de Lune to Delfine as our time in dry dock comes to an end. We're back on the water again!

Welcome aboard Delfine! This week was full of milestones. We left the dry dock, and Clair de Lune is now officially renamed Delfine. Although the journey has taken a few months, it is rewarding.

We broke our no-Sunday-work rule last week because it was a warm day. We used the opportunity to apply another coat of varnish and add more draft-stop to the windows to plug a few water leaks.

Working on the windows

It's been one of those weeks where it's hard to believe that on Monday, the then-Clair-de-Lune was still stuck in dry dock, with the propellor shaft being fitted, the propellor added, and the rudder remounted. Of course, on a boat, nothing is straightforward! Karina updated the electrical plan, marking all the switches and outlets and got that across to the architects.

Mounting the rudder and propellor again.

The rudder is attached by six bolts in a circle. That's easy enough, but the two opposing bolts, in line with the rudder, didn't have enough room to push the bolts through the holes. When the rudder was removed, we discovered that at some point, they'd avoided dealing with this by simply welding the rudder on. A bad idea! In practice, if the bolts were in place, they could be undone and the rudder removed with them still in place in the gap, but presumably, they had failed, and the last time the rudder was removed, they didn't want to deal with getting new ones fitted.

We spoke with Ronnie, our shaft guy, who's an expert on these things. We all agreed that we should do it right—no welding the rudder stock back together! After discussing how to get the bolts in, he came up with the simple solution of cutting off the top of the rudder, fitting them in, and then welding it closed again. It was relatively quick and easy to do.

With the rudder in place, the weather was just good enough on Tuesday for painting to continue. We stayed away from the shipyard, focusing on some administrative tasks instead. There's no point crawling over the boat when the paint is wet or dragging sand from the dock onto the deck. It's best to let them get on with it. I stopped by to take some photos and rode out to the chandlers for some supplies. Critically, new fenders! We don't want to damage the paintwork.

On Wednesday, we had to be at the shipyard early (8 AM), which meant riding our bikes there in the dark at 7.30 AM. This was so they could flood the dry dock enough to move the boat forward by about a metre. This lets them black the sections of the hull that have been sitting on the blocks. It's also a chance to ensure the boat has remained watertight and none of the welds leak where the overplating was done.

Early Wednesday morning, water flooding in.

This all went smoothly, and on Wednesday afternoon, we also completed welding the holes in the deck, which was a huge relief. While some welding is still needed on the bollards at the bow, we have now completed all the welds that required us to cut into the walls. The boat is watertight again. By the end of Wednesday afternoon, precisely two weeks after we entered, we were ready to leave the dry dock.

Welding. End of Wednesday, ready to exit the dry dock first thing on Thursday.

We had to be at the shipyard even earlier on Thursday! It was very cold on the deck was covered in ice, making it slippery. They started work at 7:30 a.m., and the minute we boarded the boat, they opened the floodgates to lift her again. Within an hour or so, we were afloat. We were pulled to one side, and Ronnie, the shaft guy, boarded to monitor things as we left.

Leaving dry dock and checking the shaft.

What a two weeks it's been! Eighty percent of the hull has been sandblasted, and all the rust has been removed. The hull survey and overplating have been completed. Holes in the deck have been welded. The hull has received two coats of primer, two coats of colour, and a clear coat. One coat of primer is on the deck and coach roof (another is still to go but will be done on the water). A new shaft was fitted, and the propellor was rebalanced. And that's just dry dock. We've continued to work inside on sanding and repairing things.

With Ronnie on board, we backed out of the dry dock (terrifying), docked along side the quay (even more terrifying) and then tested the prop shaft. This basically required him to monitor the shaft temperatures as we ran it at various RPM for 30 minutes at a time until we worked it slowly up to cruising speed. Everything passed with flying colours, but we have to take it slow the first few cruises to settle everything in.

The refurbished dog hatch. Karina has done a HUGE amount of work on sanding and varnishing. A reminder of what it looked like before we started. Installed just in time before the rain came.

Ronnie is a character. He's retired, but comes back to work on jobs like ours. He's been at the shipyard for over thirty years now, starting back before 1995. We learnt a lot of history about the yard from him, including the fact that during World War II, the large dry dock was used by the Germans to repair their U-Boats. I tried to find photos online, but unfortunately, haven't been able to come up with anything.

Once we'd completed testing, we moved alongside Xinix where the boat will sit for a few days until next week when she can be moved back on to the quay. Sitting alongside the quay is important as we've got a lot of work to be done and now the outside is completed and watertight, we're moving to focus on the interior.

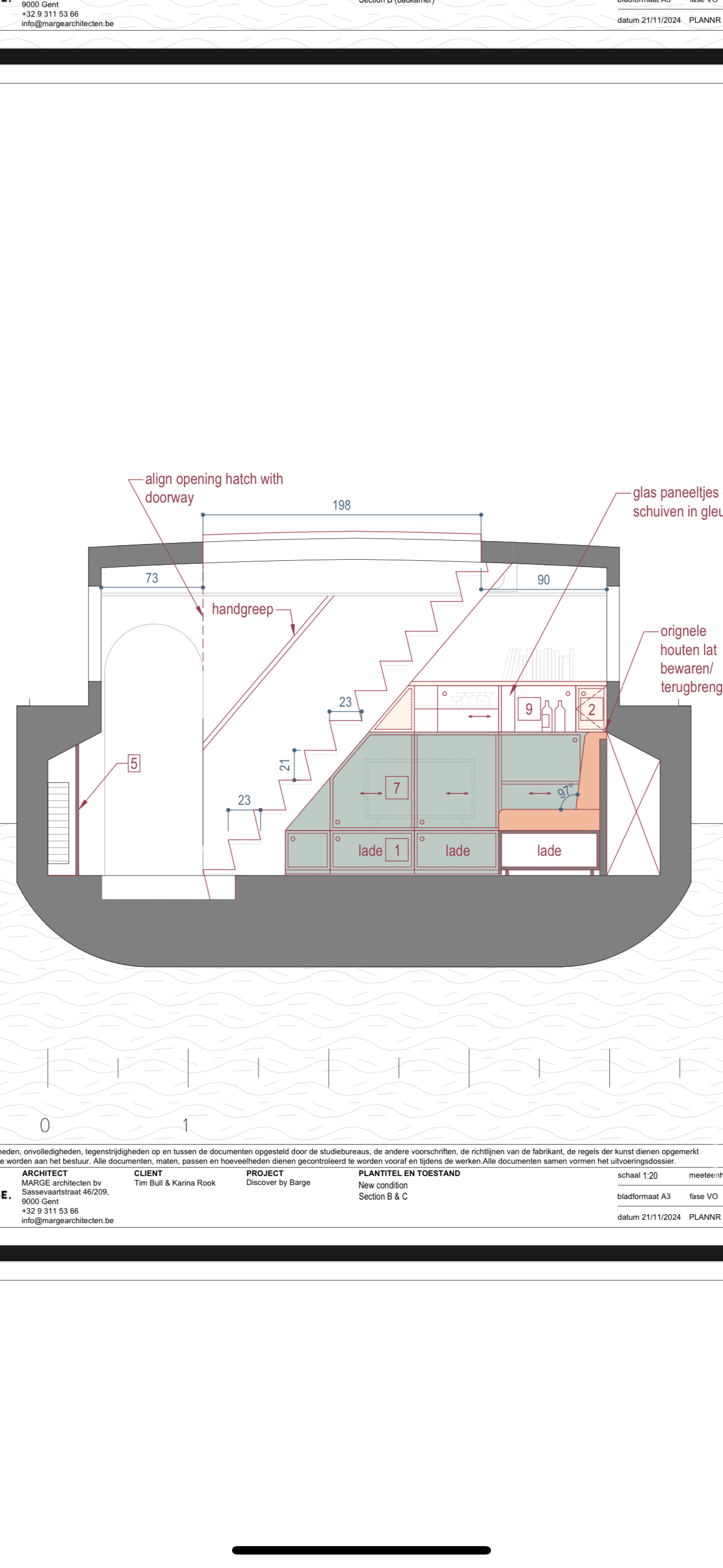

Lying alongside Xinix, back on the canal. Marking up the stairs to see how they will fit.

We started to plug the holes in the walls inside, putting back in insulation which is critical to help stop condensation with these chilly mornings.

Friday morning, we sent some updates to the architects for the electrical plan and another major milestone happened. Kevin and Dennis, from the Flemish Waterways came out to complete our tonnage certificate.

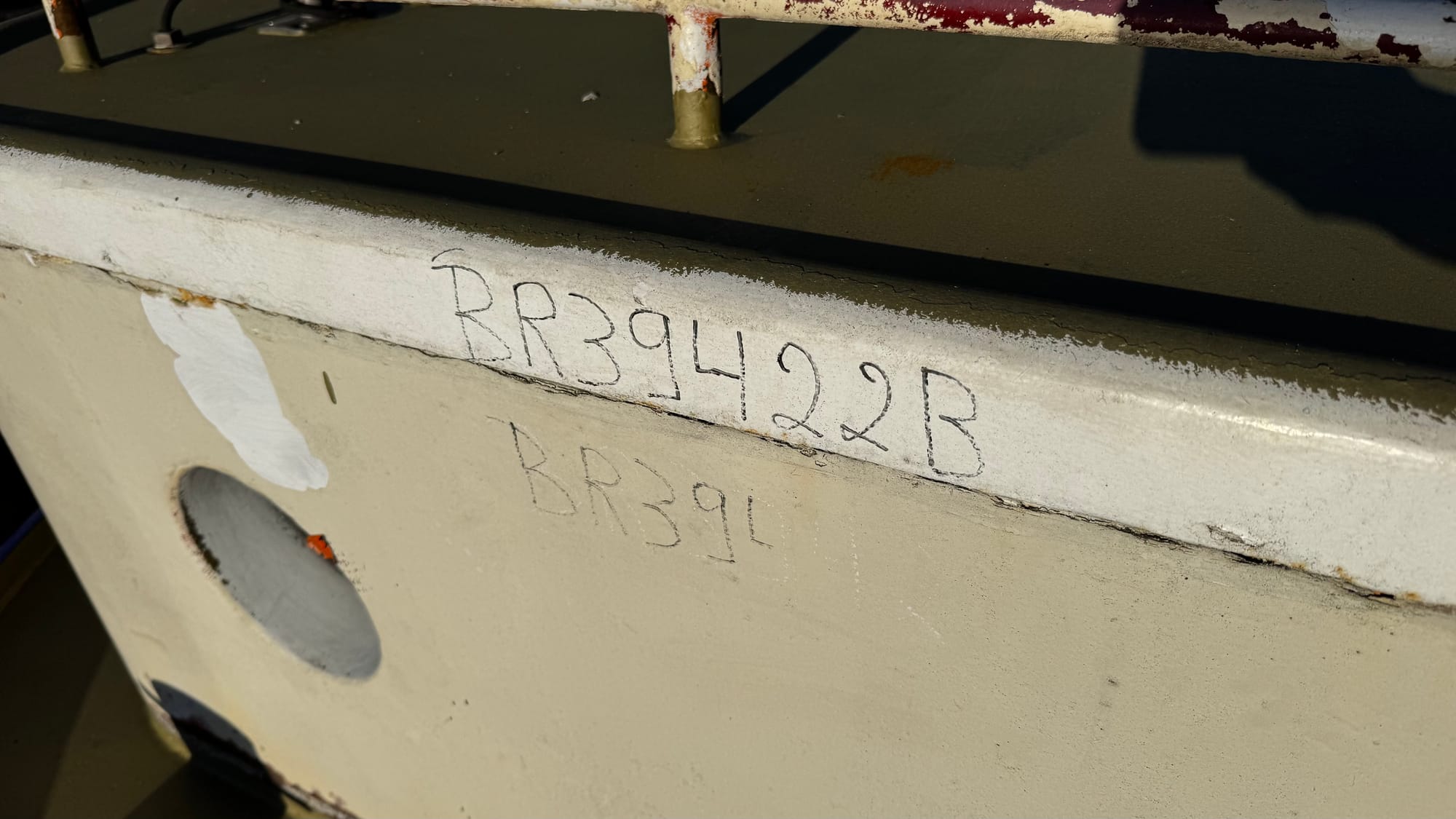

Kevin and Dennis working on the measurements for the certificate. A new number is issued and it's punched into the hull. Clair de Lune is now officially, Delfine.

For barges in Belgium, there are two critical documents. The tonnage certificate (or "Measurement document" in Flemish) which is the formal ownership document and states the physical dimensions of the boat. It's where the history and the name of the barge is recorded. It's not a survey, more a physical recording of facts. With the new tonnage certificate complete, we've been able to officially change the name. Here's a video with a bit more information on the new name Delfine and why we chose it.

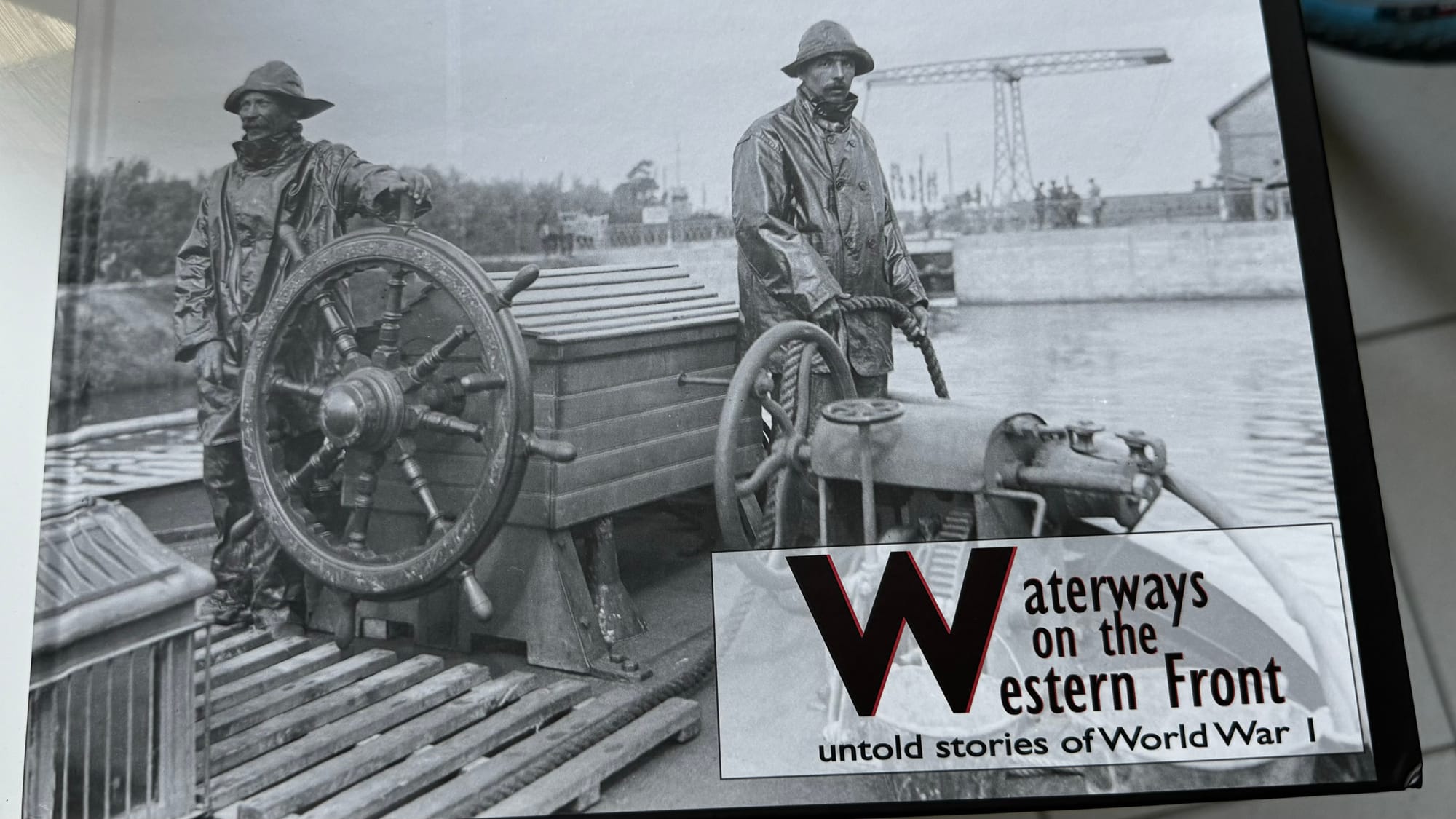

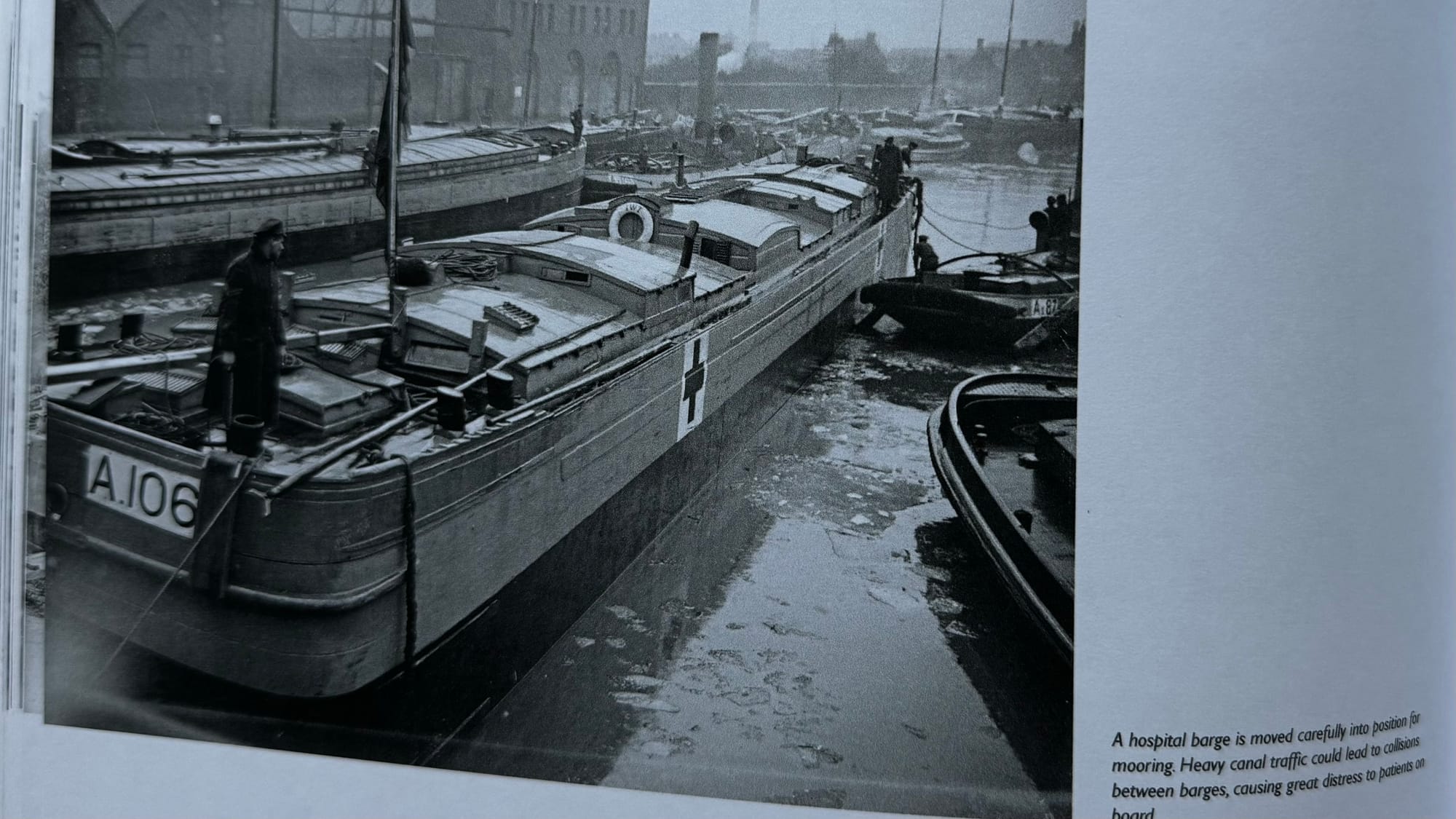

One of the fun things we confirmed during the week was about Delfine's early history. I've mentioned in the past that she was originally A.S. 270 and used in World War One by the allies. Karina read a review of a book about this history and ordered it. It's been really interesting to read through it and see boats with A.S. numbers on them, confirming for us that yes, Delfine WAS active with the allies in World War One. We're still trying to see if we can find out what role she played.

Images from the waterways in the Western Front book. Note the A.S number on barge 87.

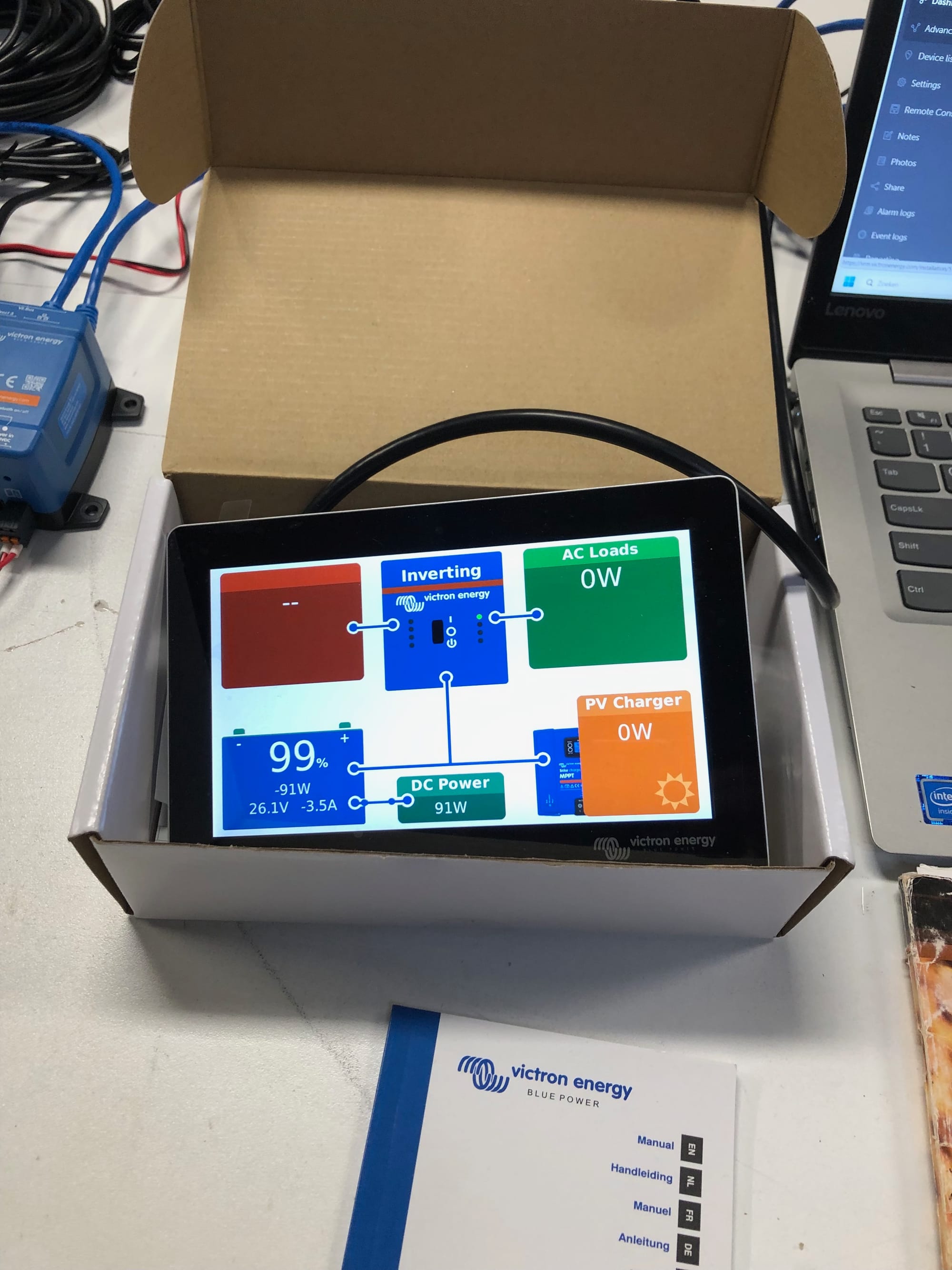

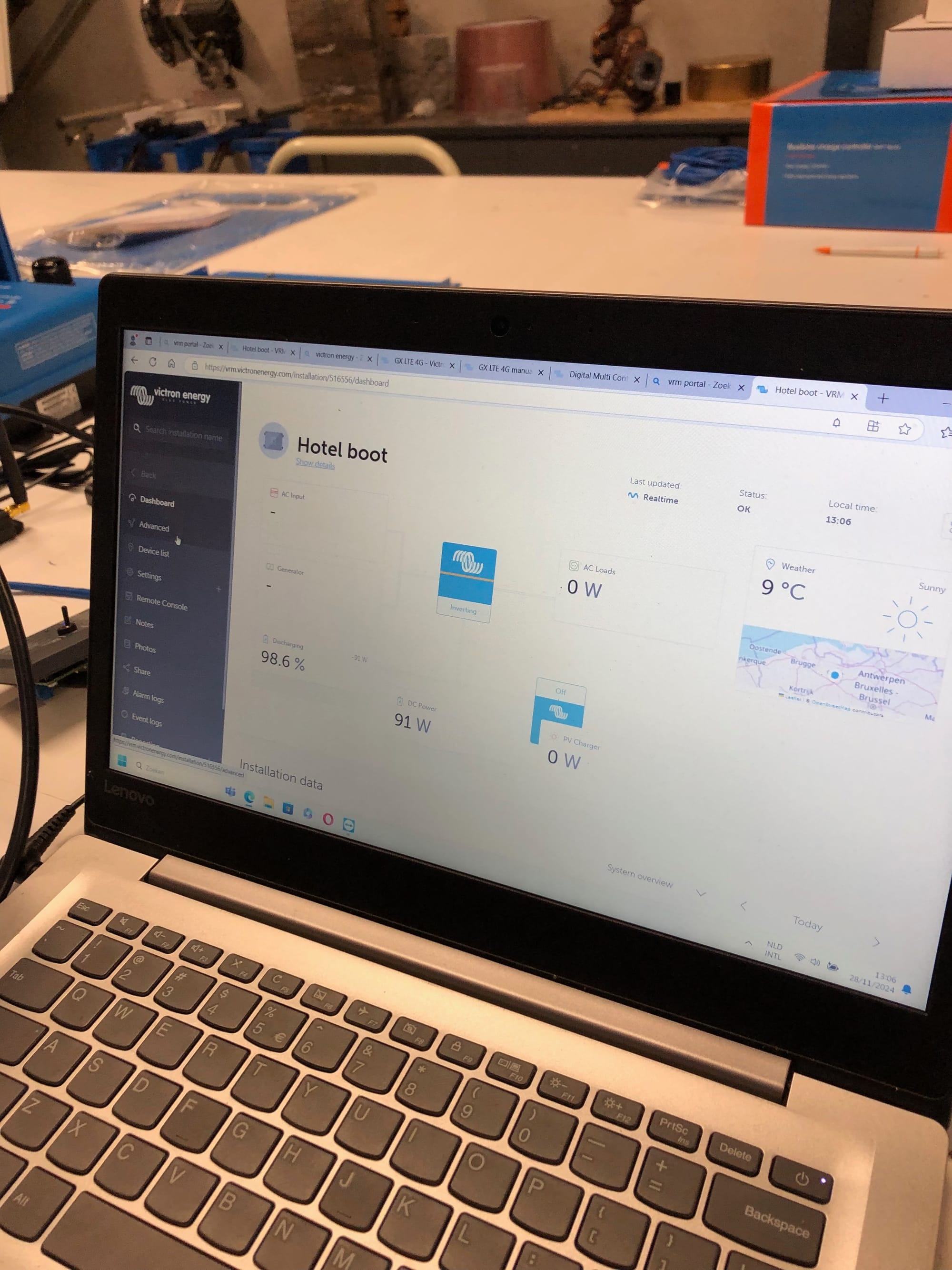

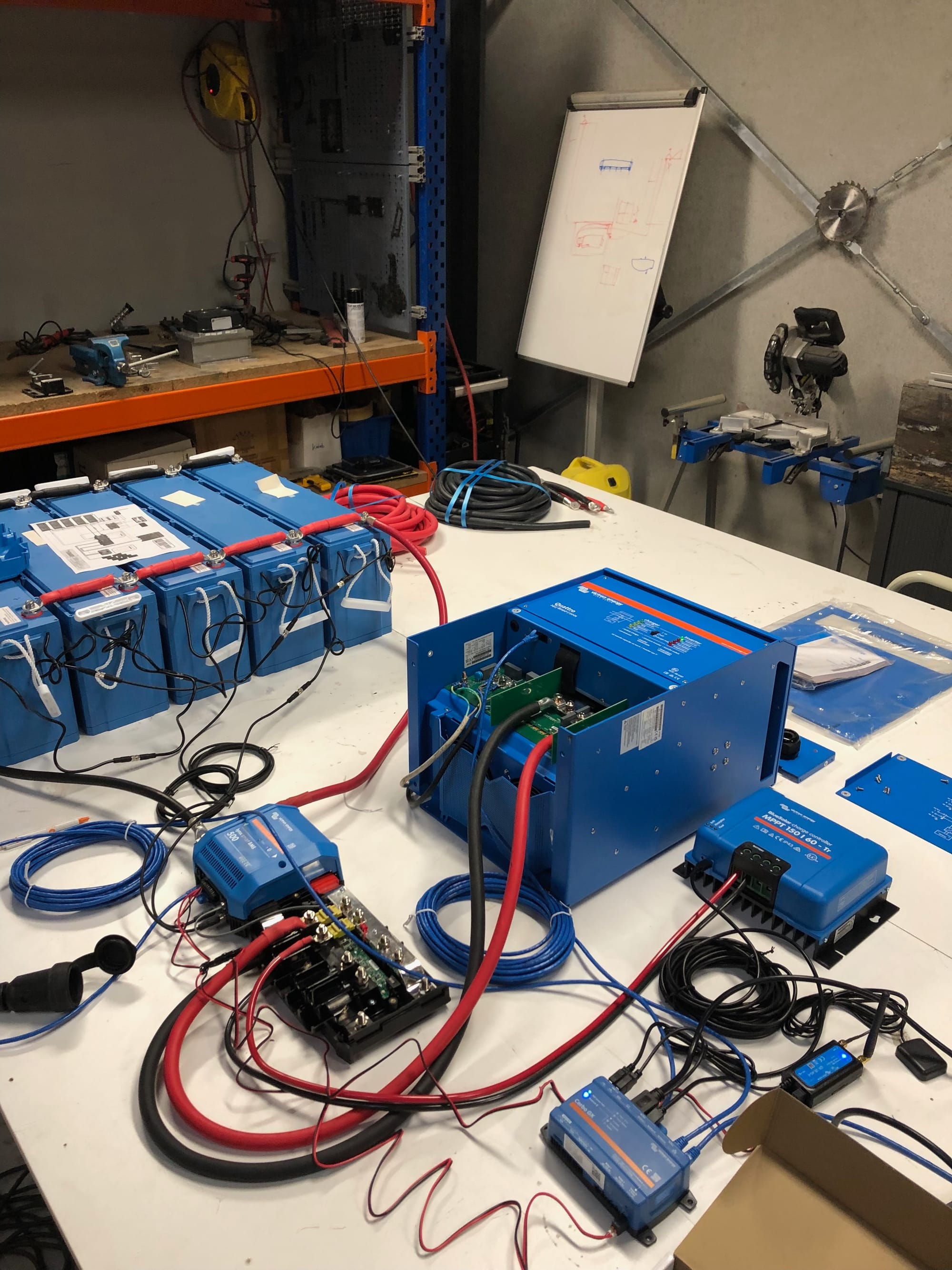

This Saturday we were back to Delfine again, this time to do some tidying. Yes, I vacuumed the engine room 🤣 It was still full of sand from the sandblasting. I suspect we'll find it onboard for years, but we're trying hard to get rid of it all. And, importantly, we now have a tidy engine room, ready for Martin from Elektro-Zeeland to start the important task of upgrading our power system and batteries next week.

Photos of the electrical build-out in testing at Elektro-Zeeland, getting configured for installation next week.

We also start on the critical task of demolition so the builders can come in and get accurate measurements for the bathrooms and kitchens.

We're very excited to finally have this milestone of the official ownership documents and rename completed. We're thrilled to be the new owners of Delfine and while there is still a lot of work to go, with the dry dock complete, we're starting to see some of the benefits of all the effort. We can't wait to share more!

Until next time,

Tim & Karina