Week 230: One stressful hole

The stress is building. We're both having trouble sleeping at times.

Measuring and trying to work out where the template will go.

Simon came by on Monday with the template for the new hatch (so the welders could mark up the size), and we spent an hour or so lining it up and trying to make it fit. We concluded that we needed to trim another few centimetres off the end to allow space for guests to turn and step off the coach roof. I woke up in the middle of the night on Tuesday morning and tossed and turned as I considered options... What about a handrail? Were the steps now too steep? Maybe we should scrap the idea?

It’s been bitterly cold and the canals partially froze. A boat we saw that looks similar to how Delfine will look when completed.

After chatting with Karina and working through it, I soon realised we had to go for it. I went to Simon's workshop to discuss the last couple of options with him. We made some further tweaks, mainly to calculate the height of the steel framework above the deck, and that's it. We were locked in.

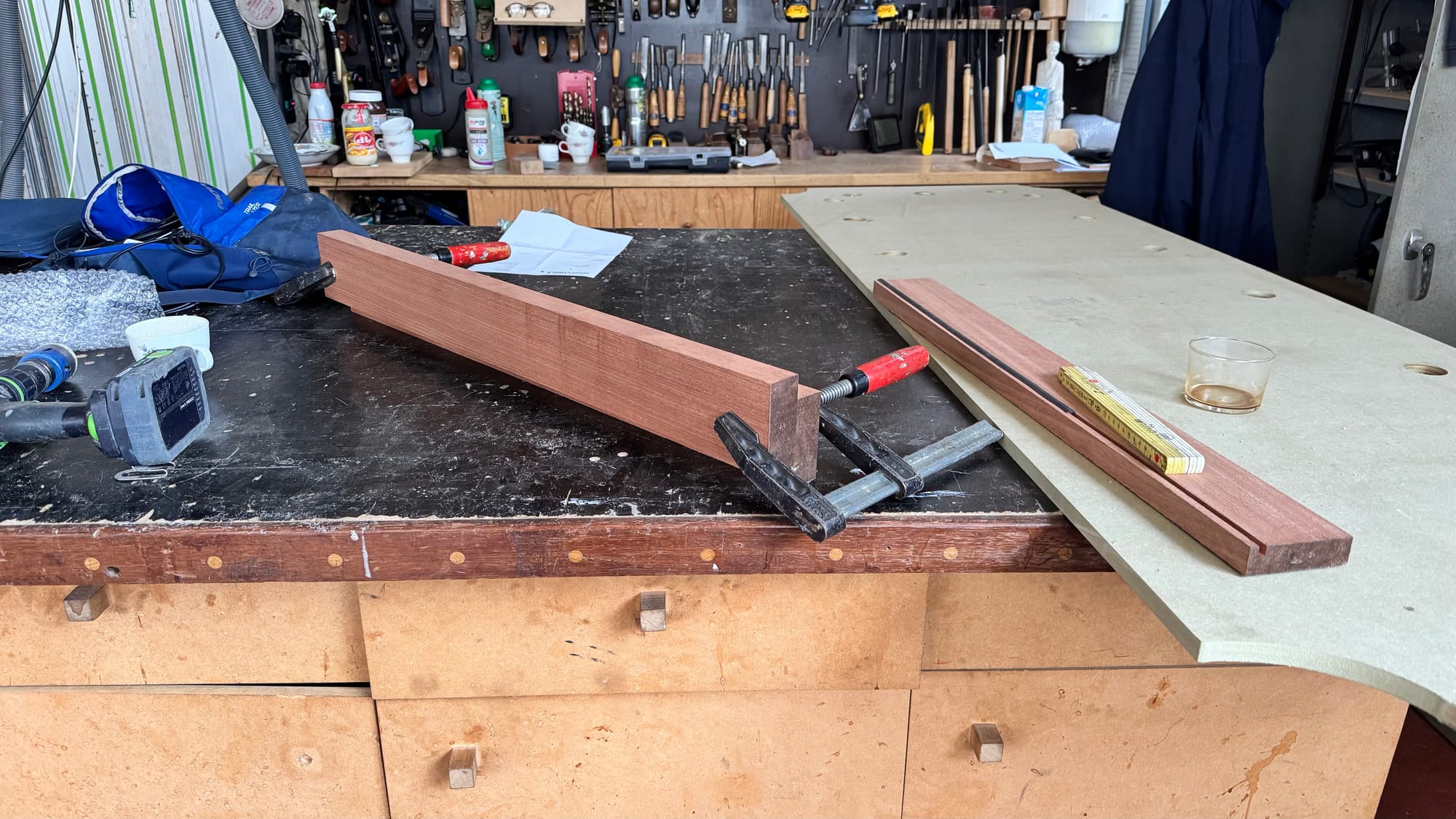

Working with wood, cutting the parts for the new hatch. Sisi the dog is the workshop supervisor

Simon's off-sider was sick on Tuesday, so he said it might take longer. Given that I was there, I offered to help. He said, "That would be great; it will let me go faster. " While he worked on plans, I tidied, removed clamps, sanded back some acrylic glue, and helped carry and move things around. It was a very satisfying day, and it improved my mood. Creating something is always more fun than destroying it. While my contribution was minor, it felt good to get my hands on the wood and take positive steps again.

A small task, fitting a cover for the hydrophore. The new wheelhouse console is ready to go and have the instruments fitted.

On Wednesday, the hatch template arrived back at the boat and Vassilis took it away to create the frame. The plan is simple enough. A 10CM box, roughly 2M long and 60CM wide. That was made to the template, and then we placed the frame on the coach roof and cut a hole.

Welders building the hatch. It was basically one day start to finish to complete the job.

Thursday morning, the metal frame returned, and we carefully positioned it on the coach roof and marked up the edges to cut out with the grinder. Boats aren't straight. The roof curves port-starboard. It leans forward stern-bow. The edge on the bow side of the roof is curved outwards towards the bow in the centre. Underneath, inside the boat, there's a lip under in the ceiling, that lip is also curved. And of course, the boat itself might be listing slightly. On the positive side, a straight edge is useless. You pick a line, you eyeball it, and you go for it.

In the end, we decided that the straight edge on the forward hatch was the right line to use–our stairs will sit parallel to that, and the rest be damned. As the welders prepared, I cut the hole inside the ceiling to remove the board and insulation for access and safety.

Very quickly, the new hole was cut in and we've got another hole in the roof of Delfine. With the hole in place, we then slid the frame inside. The plan, which worked perfectly, was to insert the middle to 5cm above the roof (our minimum height), and then the port and starboard sides drop away with the curve of the roof. Success! It all fitted exactly and within a couple of hours, it was all welded up and complete.

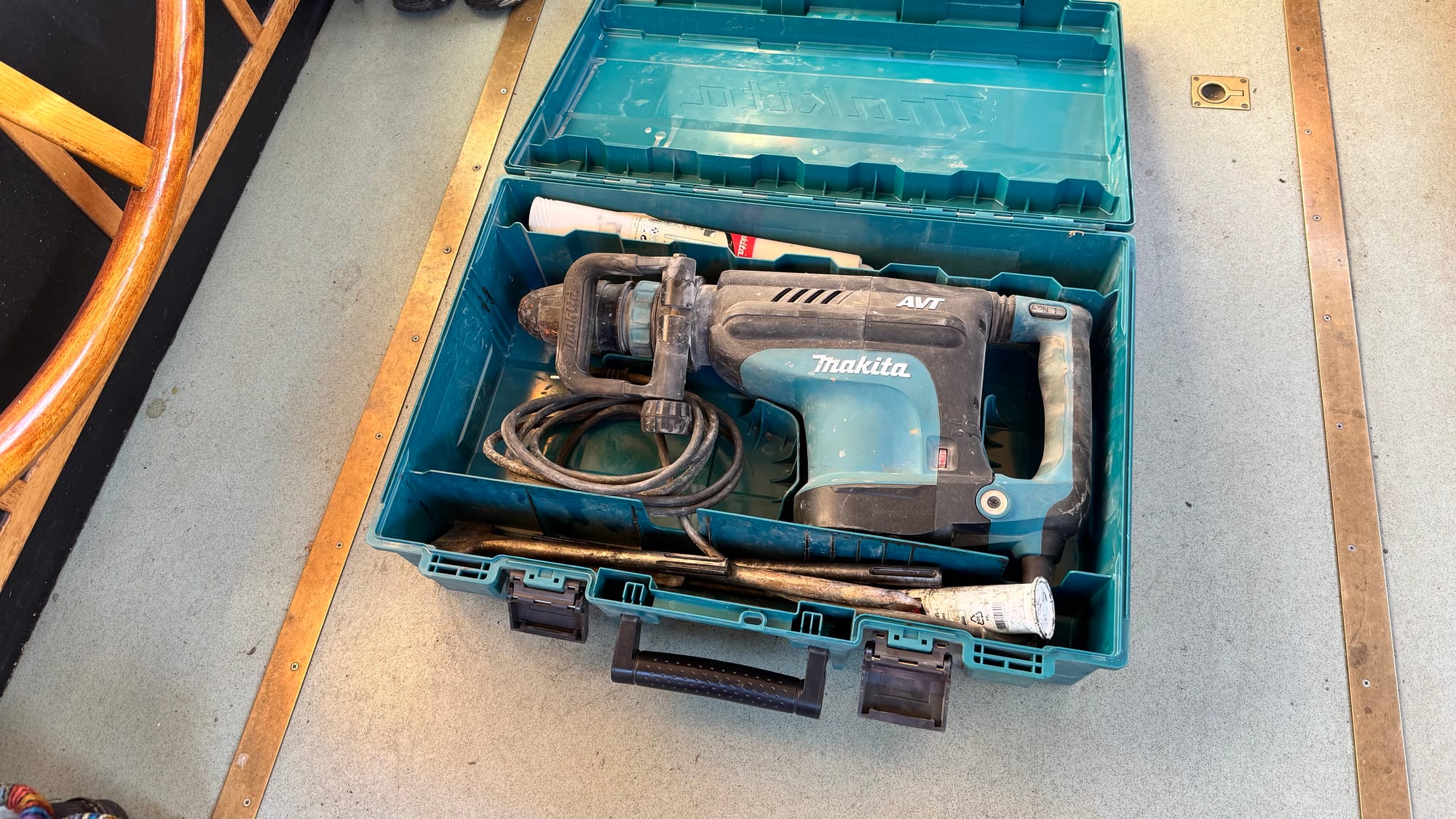

We did some other jobs too. Peter loaned me an electric jackhammer, which made removing the concrete much easier. I changed the water filters and also a valve which was broken.

What a lot of stress. Now, I feel relieved. Whatever happens from here happens. It is done and now the stairs will fit to the that as best they can, the decisions are made.

Aside from continuing to work on demolition, which is still ongoing, Karina has been very active in sanding and varnishing window frames. Now, there's only four windows left to be sanded, all about a quarter of the size of the biggest ones she's worked on, so that should go quickly.

As I was demoing on Monday (thanks, Peter, for the jackhammer!), taking out the subfloor in the shower, I hit a steel corrugation that the subfloor was floating on. This brought that to a halt while we waited for the builders to come and advise on how much of it we needed to demo.

Kristof, our project manager from the builders, brought the plumbers out to visit on Friday. There was a big meeting in the bathroom (three grown men in a tiny space), and the conclusion was reached that if I could take out the concrete OVER the metal (but not between the corrugations), they would be able to work with that and fit the new shower tray. It's a relief, as that means the end is in sight for that bathroom.

There was a list of nitty-gritty details to go over, as we get closer and closer to a contract and the building work commencing, there feels like a million tiny details to chase. Can we reuse those heaters? Do we really need that bench? Is that cupboard finish going to work? What about heat for the building process. We get urgent requests like "We need the final dimensions for the beds" leading to spending our Saturday afternoon riding out to the suburbs and visiting mattress stores to select what we need.

Of course, we learned that the lead time is 14 weeks for the mattresses we want, so we better get those ordered immediately! It's a never-ending cascade of decisions.

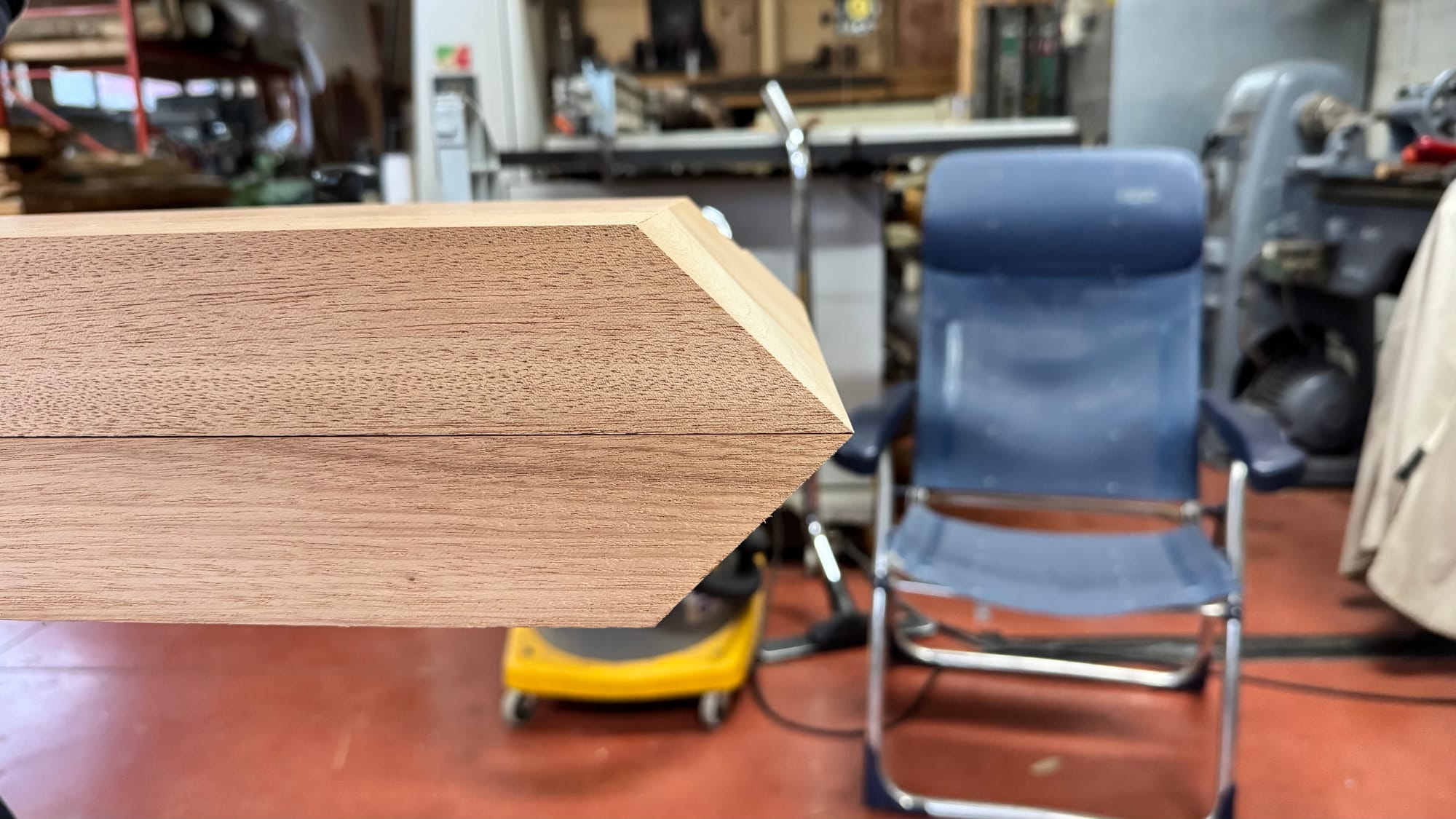

The frame with its first coat of varnish.

Finally, on Friday afternoon, Simon reached the stage with the hatch where it was ready for varnishing. We headed over to the workshop, bringing our varnishing equipment with us and had a satisfying moment of watching the wood come too life under the first coat. The hatch is beautifully crafted, and I fully expect we'll fit it next week. It's close. Two more coats of varnish and the hardware and windows can be installed. We need to finish priming the metal on the steel frame. Going well, we'll be installing it on Wednesday.

We're excited about the progress. The shipyard has also completed sandblasting for a bit so that we can clean Delfine. While we're not ready to start the final painting yet, there are a few spots we can experiment with as we finish the steel hatch frame before fitting the hatch.

Aside from the varnishing, we'll spend more time at Simon's workshop next week because the next task is the wheelhouse windows. He has time to rebuild the front hit by the bridge in Week 213: Lessons galore on the Canal du Centre. We've been discussing it, and it makes the most sense to dismantle the whole wheelhouse in one go, bring the frames over to the workshop, and we can focus on sanding them back on his benches and varnishing while he rebuilds the front window. That feels like a significant milestone in the refurbishment of Delfine! Of course, it will probably take a bit more than a week, but we're excited to dig on in and get started.

Until next time,

Tim & Karina