Week 255: Glow up

Stainless steel countertops go in, windows are fitted and lighting is installed.

After a slow couple of weeks, we dove back into the jobs on Delfine and things have started to pick up pace again with people on and off the boat most days, but also, plenty of time for us to work on tasks ourselves.

Some are less exciting than others. I spent half a day under the floor, running an internet cable to the wheelhouse and mounting the WiFi so that we can get access throughout the boat. Sadly, WiFi signals don't like steel boats, but with a separate router and a mesh extender, we now have signal into all the cabins and up onto the deck.

Some are just satisfying, like getting the horn going again. We have an air horn, which has a separate compressor in the engine room. Unfortunately, when I took the horn off last year (before we painted), I didn't immediately protect the end of the hose, and water got into the compressor. That water sat inside over winter and seized up the compressor vanes with rust. A new compressor cost over €1,000, but both Navimar and Martin said it should be possible to repair it.

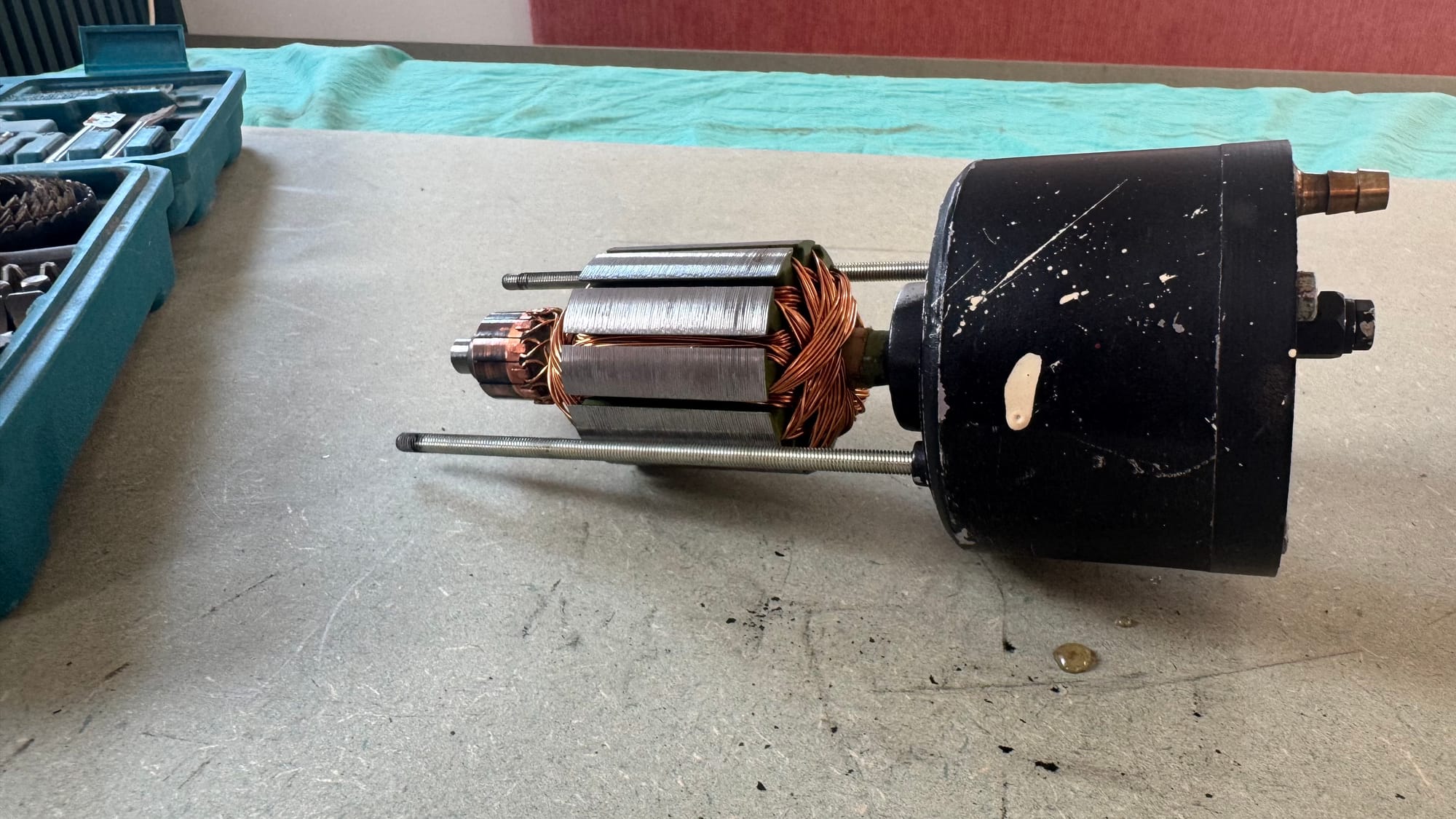

The inside of the compressor - it's those little carbon slides that jammed, and I needed to release.

The most challenging part of the job was working out how to remove the compressor from where it was mounted, but once I did, I was able to pull it apart and see what was going on. Sure enough, the "spinny" part of the compressor was seized and then the vanes were seized as well. A liberal application of WD40, degreaser, oil and repetition finally loosened it all up, and now, it works better than ever. I suspect one of the vanes on the compressor has been seized for a long time.

We'd had a lot of debate about the sliding cupboard doors and what colour to paint them. We were leaning towards pink, but everyone else suggested doing them the same green as the cabinets in the salon. We decided to bite the bullet and make that happen, and Karina spent some time prepping and painting those. Wow! What a difference. With the new brass handles inserted, they are quite spec'y now.

Simon and Jones returned to work on the hatch. It has been installed for 4 months now, through a range of different weather conditions, and on closer inspection, it needed some adjustment. The leak was fixed by removing the glass and re-sealing it. However, Simon also noticed that the bottom frame was warping slightly. The large pistons that raise and lower the hatch exert approximately 150 kg of force. This caused the frame to warp somewhat over time. They removed it, straightened and adjusted it, then changed the way the pistons mount (they now go directly to the metal frame underneath). As a result, the hatch shuts and opens smoother than ever before and should no longer have any problems. It's one of the fun aspects of building one-offs; there's always a lot to learn and consider, and you have to be prepared to adjust as you go.

Working on the hatch and making some adjustments

After putting off the inevitable, I decided it was time to tackle the remaining salon window, which was also leaking. It's fun to reflect on just how far we've come with our skills, tools and knowledge of the boat. The last window I removed was a massive undertaking. It took almost two days to remove the frame, picking the silicon by hand, bit by bit. Now, it took about 30 minutes with the multi-tool.

Removing and reseating the window frame.

It proved to be the right decision. The seal around the frame had all deteriorated, and the patch I'd tried to make wasn't good enough. Underneath the frame was full of water. With the frame removed (and the correct tools and new knowledge), it was trivial to sand it back to bare metal, apply several coats of primer, and this time (unlike the earlier ones), also add the between and finish layers. The window frame is back in place now, and I'm confident that it won't leak anymore. While I was painting the window recess, I also painted the mount for the AC, which looks great now.

The weather was quite warm outside (30+ on several days), so we were avoiding sanding the outside, but that's imminent. We prepped and painted the anchor windlass, which now only has one coat left to apply. With cooler weather and a bit of rain (which helps keep the dust down), this week, we'll tackle prepping and sanding the rest of the side panels.

Painting the windlass.

After the visit from Ella, Inge, and Gro, Karina has been adding numerous small touches to the interior. Blankets for the end of the beds. A new table for the salon. An outdoor table and an extra chair on the guest deck. More dining chairs. All the things we missed when they were here. Delfine is becoming very cozy.

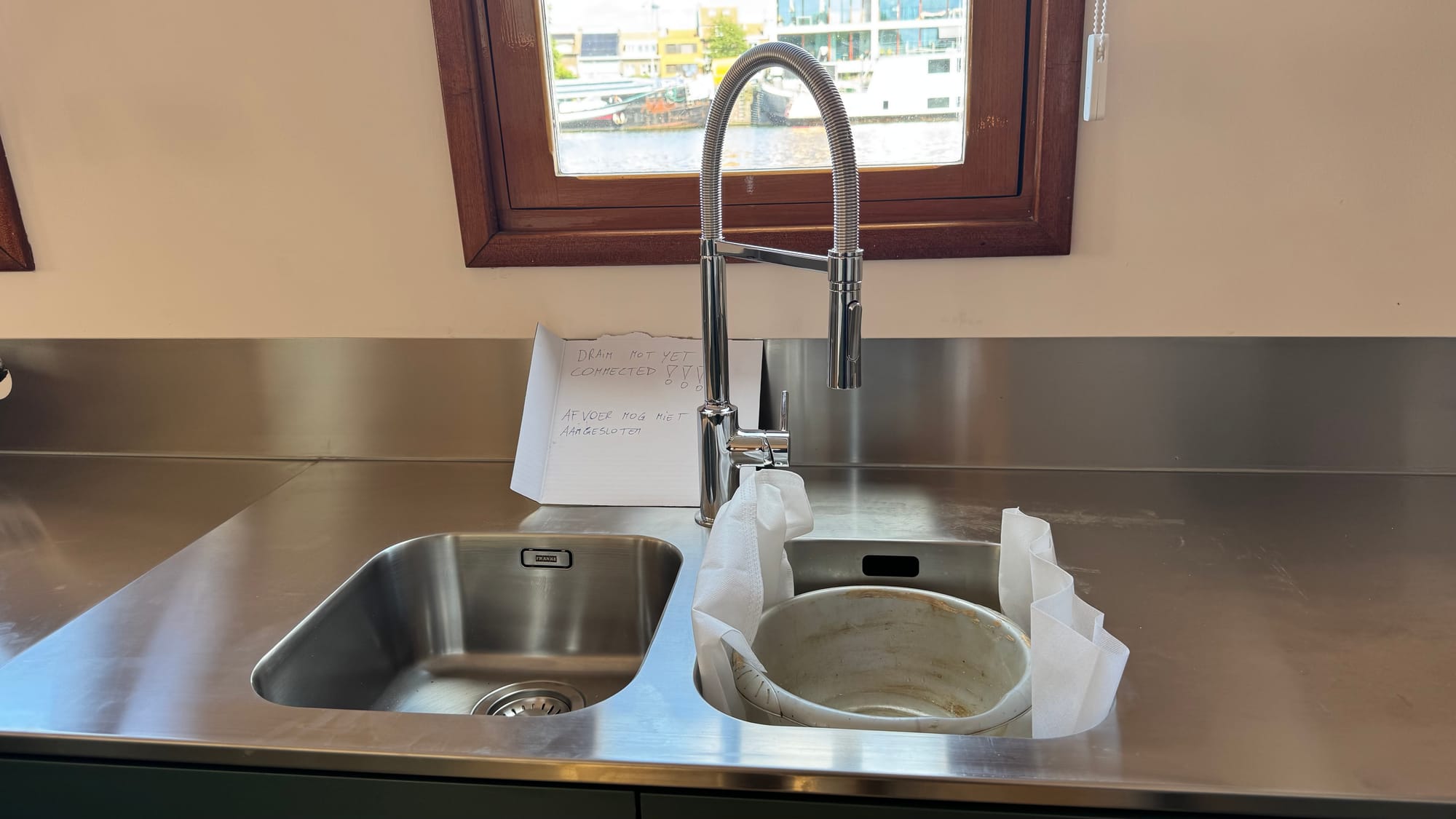

The stainless steel arrived on Thursday for the kitchen countertops. Overall, it looks great, but there are a couple of minor adjustments and follow-ups that need to be made. The seams were intended to be welded on-site, but this didn't happen.

Installing the stainless countertops

With that in, we now have a kitchen tap in our sink! But no drain yet 🤣. That will happen on Monday or Tuesday.

Frederic returned and, in addition to fitting the taps in the kitchen, he also installed most of the lighting in the salon and mounted the feature lights on the walls. Another big leap forward.

Now, we wait for the builders to complete the work under the stairs and in the stern cabin. They need two more days, and it will all be done. It's so close; it's now just a matter of scheduling it. Fingers crossed, that will be this week.

With the stair hatch now refined and improved, Simon was able to fit the last of the windows on the front of the wheelhouse on Saturday. It's wonderful to be able to look out the front again, finally!

Simon working on the installation of the final two windows. These are in two halves, and the top section can be lifted to allow air to flow through when underway.

A delightful highlight of the week was on Friday afternoon when the team from Marge Architecten came to visit. Before summer break, the whole office goes "on tour" and visits all the projects they are working on—a chance for them to learn and share. We prepared numerous before photos, which we displayed around the boat. I think the most fun for Karina and me was hearing their reactions to what they were seeing – for most of them, it was their first time on Delfine. There was more than one comment about how they could see themselves on a luxury holiday on board.

As we get closer and closer, the big question is always "When will you have your first guests?" The answer is always "finish first, then photos, then bookings."

We are not yet finished. However, we've booked a photographer in a couple of weeks to take the photos that we can use to attract bookings. At this point, we're close enough that the large unfinished items (the wall above the stairs and the crew cabin) won't stop us from taking photos that we can use to show Delfine to the world.

Our world revolves around our punch list of tasks to be completed. It gets reordered and reprioritised depending on the needs of the day, but now, it's "What looks good in photos" that's taking the priority!

With luck, this week will see the two guest bathrooms completed (at least, to the point they are usable – delays on the correct shower mixer mean the final "completion" to spec might not be for a few more months), which makes us itching to start cruising and exploring our route.

It's getting very close.

Until next time,

Tim & Karina